Archiwum dla miesiąca: January 2015

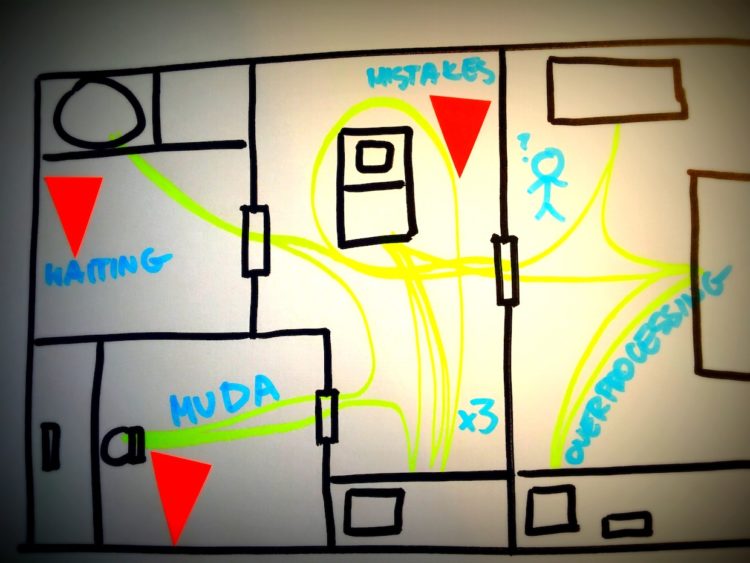

Spaghetti Diagram

Spaghetti plot is a professional tool used to analyze current process flow. It is aimed at creating a visualization of worker’s movement and the material flow within a process in order to present the current waste and problems.

To create a spaghetti plot analysis it is important to

- Select the process that must be optimised.

- Get to know the individual steps of the process and create a simple flowchart.

- Choose employee or position, that will be observed.

- Prepare a sheet of paper and a pencil and some sticky notes.

- Keep an eye of the worker and draw the path he repeatedly walks. If some activities turn out to be incomprehensible it is necessary to ask some questions to the participants of such a process.

- During the process observation all muda (waste) concerned with lean healthcare such as waiting, errors or superfluous transport should be marked.

Analysis can be done in a specified time period which may be shorter than the shift duration – often determined as 8h.

All marked movement of a worker needs to be analyzed in the next step to find any bottlenecks or tasks which were the main waste to lean healthcare e.g. excessive activities or transport, waiting and errors. The aim is to introduce updates and solutions that would eliminate or minimise the located problem and waist.

What should one pay attention to while observing and generating solutions with use of spaghetti plot?

- collect feedback from employees

- collect feedback from management regarding current issues and planned rearrangement in the process

- take workplace health and safety into account

- take into account all legal requirements and regulations

Results

After carrying out analysis and proposing solutions it comes time to take action and implement created solutions in the process. This should be a smooth transition from analysis to action stage – implementation without waiting as this might generate new changes in the process. The longer it takes to implement proposed changes the greater the risk that they will not fit to current process that may suddenly change. A very important issue is the engagement of operative employees in creating changes and collecting comments about their “dream” workplace. Lean healthcare philosophy concentrates on person and its approach to work. Despite good analysis and rapid implementation of improvements, the project may not work out because employees wont adapt to new adjustments. Approach to such a technique should be strategic, taking into account actual needs and ideas of staff by allowing them to actively participate in the analysis and improvements. Joint decision concerning a process will result in partial responsibility that lays on employees for their work and greater efficiency of implemented changes.

It’s a quick and cheap method that allows to capture current problems of a process. Project success, that is, implementation of the proposed improvements will depend on engagement of personnel and collecting detailed information about the process.

About Lean-hospitals

Lean Hospitals is a lean management philosophy which originates from lean manufacturing and lean management. Strongly associated with efficient approach towards clinical processes management. Initially used in production but afterwards it became popular in medical services. Today determined as lean hospitals it is concerned as lean management of hospital (every medical unit). Why did healthcare management considered methods we mentioned? It’s because simplicity involves cheap management tools introducing time and financial savings (eliminates waste).

Pros of this technique:

- increases safety of patients and staff

- simplifies clinical processes

- shortens hospital stay

- rationalise work of medical staff

- reduces costs of medical services and functions in medical units

- boosts business efficiency

Stosowanie narzędzi szczupłego zarządzania pozwala na lepszą współpracę zespołu medycznego. Poszczególne narzędzia można stosować do wybranych procesów, niekoniecznie kompleksowo.

What do we improve?

- shortening distance made by nurses or ward nurses during activities like administering medications or changing beddin

- speeding up information flow amid reception desk, patient, family and physician

- support exact order of ward, surgery, reception desk, utility rooms

- unify and simplify instruments sterilization process

- reduce storage space of dressings and medications. Maintain financial liquidity.

Above mentioned improvements are few out of many that we can frequently observe in hospitals around UK, United States or Japan. Lean hospitals is a completely new approach and its derivative techniques originating in todays production can easily evoke doubts. In contrast, it may give rise of rewarding benefits creating another dimension by way of treatment and medical process management.

Kaizen – how to reinfuse the change in patient life?

Japanese philosophy of small steps can trigger in employees desire of implementing changes and actively engage people to improving clinical processes. This also influences on patient and their motivation. Gathering ideas from employees is one thing, implementing solution and maintaining is difficult task is another thing, but possible to realize.

While patient sees his bad test results is scared and doesn’t know what to do. As Milosz Brzezinski writes “there is a tendency for expire the emotions, so after some time determination for obey difficult rules comes down. The mind doesn’t have his own way for long-term sustaining decisions. That’s why is better to show patient, that something is easier energy-related, for example: closer is go to the greengrocer’s shop that chemist’s. If somebody has to walk everyday, it would be easier with shoes lay down next to the bed; then patient shoe and will be easier to get out home(…) if somebody cannot mobilize for 20 minutes running, should focus on any walk” Miłosz Brzeziński, Puls Medycyny nr 6, kwiecień 2016.

If you want to implement Kaizen in your company- hospital, outpatient clinic or other medical unit, it is good start from learn about that, collect some practical examples from other hospitals, benchamrking. Mainly, implementing kaizen has no sense, if it’s forced, because kaizen approach is a continuous process. It is not a project, which as finished you can summarize and collect results. Once well implemented philosophy kaizen could be acceleration for continuous improvement and succeeding lean healthcare tools. If employees- physicians, nurses, technicians, medical caretaker and top management actively and permanently engage in change process, it will be success for entire hospital.

Proposing ideas, which can inspire other shouldn’t be intrude (some corporation force employees to report for example minimum 5 ideas/person/quarter, as KPI for each department). This is not compatible with Kaizen philosophy. I disagree with this approach. Usually, ideas comes spontaneously, not imposed, that’s why great ideas were made in different situation, not working at desk but meeting with people in gemba.

The process of reporting ideas in medical unit should be standarized, described, the best in visual way and public for all employees. The possibilities of reporting ideas shouldn’t be divided into group. Every of employee should have the same possibility to report improvement- if it is nurse or medical staff, they also can report some idea for administration department and conversely.

After message of optimization clinical process or other, team (the best way is to have top management as main nurse, unit manager and worker) read all ideas and giving them level of priority. Every idea should be appreciated, rest which will be implement into real life should be particularly awarded. Medical staff should feel appreciated and motivated for further actions.

How often should we organize summarize for reported ideas? Well, the findings can be tracked online, summarize meeting can be organize quarterly or half-yearly. This meeting is rather gathering data and giving feedback than people motivating. Motivation should be conducted complete year, day by day.

Advantages:

- Medical staff and administration is valuable source of information and ideas for hospital.

- Improvement communication process in organization.

- Increase employee engagement- also this is TWI element.

- Improvement patient safety.

- Knowing by employees problem solving tools.

- Eliminating muda.

- Descrease costs of hospital functioning.

- Improvement patient care quality.

- Prevention of infection.

Rules:

- Each, reported idea is valuable and should be discussed by kaizen team. Think about how to do it, rather than why can’t we do it.

- Practise japan rule of small steps. It’s better improve something about 30% than doing nothing. There is no possibility to create ideal process first time.

- Kaizen team should systematically browse ideas.

- Every reported idea is appreciated. Internal employee motivation should be fulfilled.

- Kaizen is never ending story- process.

In conclusion, kaizen is first step to work organization according to lean healthcare approach. Solve the problems, without blaming.