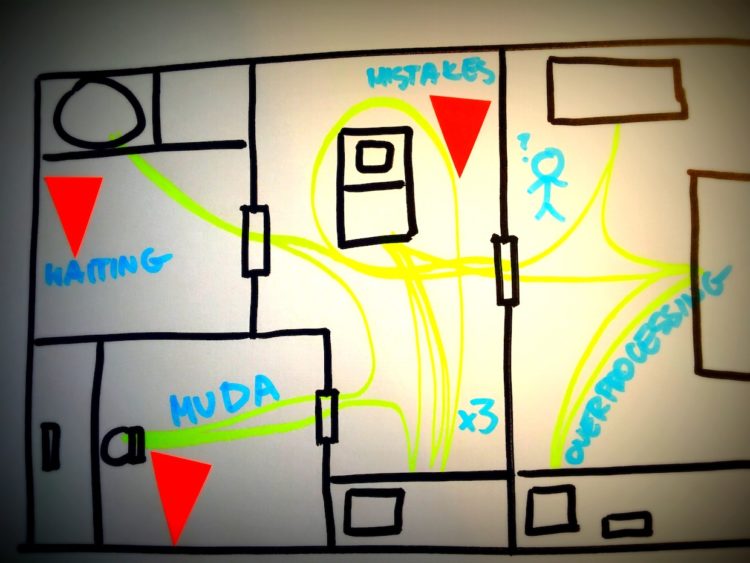

Spaghetti Diagram

Spaghetti plot is a professional tool used to analyze current process flow. It is aimed at creating a visualization of worker’s movement and the material flow within a process in order to present the current waste and problems.

To create a spaghetti plot analysis it is important to

- Select the process that must be optimised.

- Get to know the individual steps of the process and create a simple flowchart.

- Choose employee or position, that will be observed.

- Prepare a sheet of paper and a pencil and some sticky notes.

- Keep an eye of the worker and draw the path he repeatedly walks. If some activities turn out to be incomprehensible it is necessary to ask some questions to the participants of such a process.

- During the process observation all muda (waste) concerned with lean healthcare such as waiting, errors or superfluous transport should be marked.

Analysis can be done in a specified time period which may be shorter than the shift duration – often determined as 8h.

All marked movement of a worker needs to be analyzed in the next step to find any bottlenecks or tasks which were the main waste to lean healthcare e.g. excessive activities or transport, waiting and errors. The aim is to introduce updates and solutions that would eliminate or minimise the located problem and waist.

What should one pay attention to while observing and generating solutions with use of spaghetti plot?

- collect feedback from employees

- collect feedback from management regarding current issues and planned rearrangement in the process

- take workplace health and safety into account

- take into account all legal requirements and regulations

Results

After carrying out analysis and proposing solutions it comes time to take action and implement created solutions in the process. This should be a smooth transition from analysis to action stage – implementation without waiting as this might generate new changes in the process. The longer it takes to implement proposed changes the greater the risk that they will not fit to current process that may suddenly change. A very important issue is the engagement of operative employees in creating changes and collecting comments about their “dream” workplace. Lean healthcare philosophy concentrates on person and its approach to work. Despite good analysis and rapid implementation of improvements, the project may not work out because employees wont adapt to new adjustments. Approach to such a technique should be strategic, taking into account actual needs and ideas of staff by allowing them to actively participate in the analysis and improvements. Joint decision concerning a process will result in partial responsibility that lays on employees for their work and greater efficiency of implemented changes.

It’s a quick and cheap method that allows to capture current problems of a process. Project success, that is, implementation of the proposed improvements will depend on engagement of personnel and collecting detailed information about the process.